O JetX da Smartsoft Gaming, revolucionou o mercado de crash games e se tornou extremamente popular não apenas no Brasil, mas em todo o mundo. Os jogadores adoram o JetX por sua dinâmica, jogabilidade viciante e ainda a possibilidade de receber uma renda real. O simulador de arcade, que lembra as máquinas caça-níqueis, apresenta uma interface simples, rodadas rápidas, e um alto nível de RTP. O jogo multiplayer de última geração tem uma mecânica simples que permite fazer apostas de baixo valor e ganhar prêmios valiosos.

Informações básicas sobre o jogo:

| 🎲 Provedor do jogo | Smartsoft Gaming |

| 🕗Data de lançamento | 2019 |

| 🎮Modo demo | Sim |

| 📈 RTP | 97% |

| 💸Alavancagem mínima | x1.00 |

| 💵 Aposta mínima | R$ 0,5 |

| 🚀 Aposta máxima | R$ 3000 |

| 💎 Prêmio máximo | x1000 |

| 📱 Dispositivos no quais se pode jogar | Celular/PC |

| 🖥 Tecnologia | JS, HTML5 |

| 🎮 Jogos alternativos | Aviator, Zeppelin |

O JetX é um crash game criado pela SmartSoft Corporation baseado em um sistema de segurança Provably Fair (Jogo Comprovadamente Justo), que garante uma correspondência 100% aleatória dos resultados e imparcialidade na jogabilidade.

O JetX do provedor Smartsoft Gaming, chegou ao mercado em janeiro de 2019, provocando uma forte reação dos apostadores. Os jogadores comparam o JetX a uma máquina caça-níquel. Alguns jogadores o consideram um jogo arcade, com rodadas rápidas, apostas em tempo real e grandes prêmios.

O JetX se diferencia dos caça-níqueis tradicionais, pois tem interface mais avançada e abordagem exclusiva em relação à jogabilidade: é possível escolher o momento de saída do jogo para ganhar. Trata-se de um novo gênero de jogos de apostas no qual a sorte se combina com um pouco de estratégia.

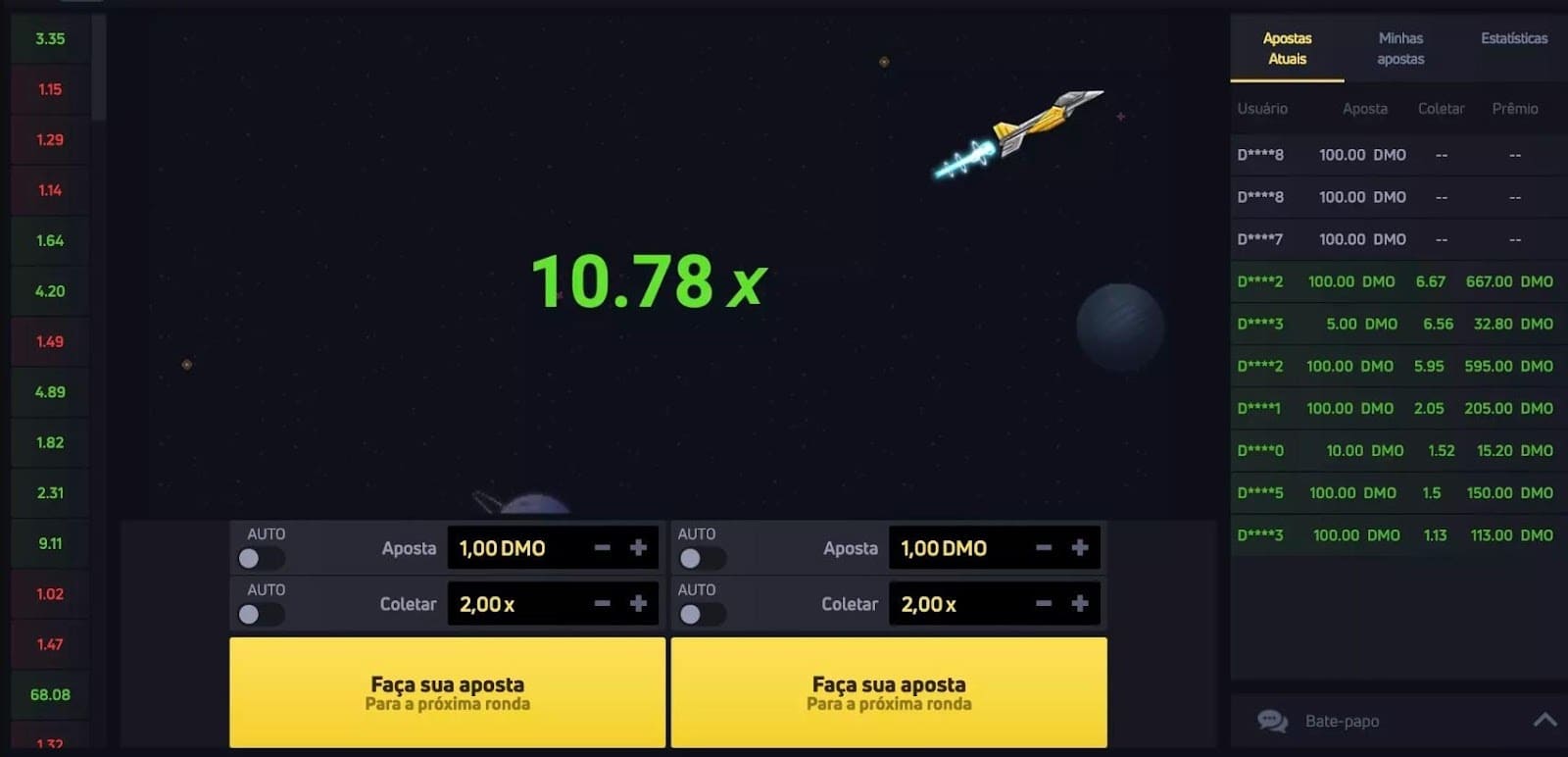

O objetivo do Jet X é seguir a trajetória de um pequeno foguete à medida que ele sobe. O prêmio corresponde ao valor da aposta, multiplicado pelo multiplicador no momento da retirada. O prêmio é garantido se você retirar a aposta antes que o foguete exploda. A queda do foguete indica que você perderá tudo, a aposta e o multiplicador.

Resumindo, a tarefa é adivinhar o momento exato de resgatar o dinheiro antes que o foguete exploda, ganhando assim o prêmio máximo. É preciso ter muita sorte, pois nunca se sabe quando o foguete irá cair. Tudo isso aumentou o interesse por este jogo divertido, a emoção e proporciona uma boa dose de adrenalina, com as dificuldades durante o jogo.

As regras do JetX são fáceis de entender e de seguir:

A popularidade do JetX se deve ao alto nível de RTP: 97%. Este parâmetro indica a porcentagem média de dinheiro que o jogador recebe de todas as suas apostas ao longo de um período. As máquinas caça-níqueis por sua vez, geram um retorno médio de investimento de 96,00%, sendo, portanto, este valor inferior à média do JetX Bet.

SmartSoft Gaming: uma das maiores empresas de desenvolvimento no segmento de jogos de apostas, garante alta segurança e resultados aleatórios nas sessões de jogos usando a tecnologia blockchain, que não pode ser adulterada. Ou seja, a jogabilidade no JetX é justa e a total segurança e confidencialidade dos dados pessoais é garantida.